PLANT & SOIL SCIENCES FACT SHEET TOB-1-05

![]()

Proper

Curing Management to Minimize

the Occurrence of Houseburn in Tobacco

By Andy

Bailey, Extension Dark Tobacco Specialist, and Gary Palmer, Extension

Tobacco Specialist

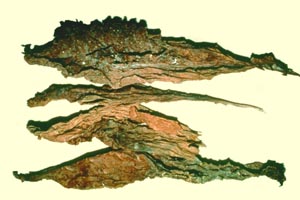

Properly cured tobacco requires mean daily temperatures of 65 to 85° F, mean daily relative humidity of 65 to 70%, and a minimum airflow of 15 ft/min (0.17 mph). When these conditions fall outside of the optimum ranges given, several problems can occur which can result in poor quality tobacco regardless of the quality that was achieved in the field. Just as low temperatures and, to some degree, low relative humidity can result in green tobacco; the opposite conditions can result in houseburn. Houseburn, sometimes called barn rot or pole rot, is caused by high humidity with moderate to high temperature. Houseburn results in dark leaf with excessive losses in dry weight resulting primarily from the action of microorganisms that cause soft rot.

During

warm weather with relative humidity above 75%, the drying rate should be

increased to prevent houseburn. Under humid conditions, ventilators should

be opened to enhance drying and fans should be used to move air if possible.

When conditions favor houseburn, increase air movement within the barn as

much as possible to lessen the chance of houseburn. Since there is no upper

limit to air flow when temperature and relative humidity are within the

acceptable range, it is advisable to open ventilators and use fans during

normal and humid weather that usually occur during the first three weeks of

the curing process. Air movement throughout the barn is important so that

houseburn does not occur in spots in the barn where air movement is

restricted. If doors or ventilators are only opened on one side of the barn,

air flow is restricted and houseburn can occur on the side where the doors

or ventilators are closed.

During

warm weather with relative humidity above 75%, the drying rate should be

increased to prevent houseburn. Under humid conditions, ventilators should

be opened to enhance drying and fans should be used to move air if possible.

When conditions favor houseburn, increase air movement within the barn as

much as possible to lessen the chance of houseburn. Since there is no upper

limit to air flow when temperature and relative humidity are within the

acceptable range, it is advisable to open ventilators and use fans during

normal and humid weather that usually occur during the first three weeks of

the curing process. Air movement throughout the barn is important so that

houseburn does not occur in spots in the barn where air movement is

restricted. If doors or ventilators are only opened on one side of the barn,

air flow is restricted and houseburn can occur on the side where the doors

or ventilators are closed.

Heat can also be effective to reduce houseburn. The use of gas heaters or even small charcoal fires under the tobacco during the early stages of curing raises the temperature of the air entering the tobacco from below, thus increasing the moisture-holding capacity of the air and decreasing the relative humidity. It is the lowering of the relative humidity that alleviates the houseburn. During houseburn conditions, it may be necessary to open all of the ventilators and maintain a low fire to drive out the moisture. However, the exposure of tobacco to compounds released during combustion of most fuels has been shown to elevate tobacco specific nitrosamines.

Proper housing is also important to deter the chances of houseburn. As a general rule, tobacco should be properly wilted before housing and five or six plants should be put on a stick. Sticks should be spaced eight to twelve inches apart on the tiers. Additionally, the tails of the tobacco should not lap over the butts of the tobacco on the tier below. Tall tobacco may be housed by alternate hanging of the sticks, so that the tails hang freely between the butts of tobacco on the tier below. For extremely tall tobacco, alternating tiers can be used if barn space allows. Housing tobacco with sticks too close together or where tails overlap butts on the tier below decreases air movement through the tobacco and can increase the chances of houseburn. In dark fire-cured tobacco, sticks spaced too closely also decreases the contact of smoke onto the leaves.

Many air-cured tobacco crops that were high quality in the field have resulted in mediocre or even poor tobacco coming out of the barn due to poor curing conditions. With good curing weather and judicious barn management to optimize weather conditions, we stand a better chance of assuring that the high-quality tobacco going into the barn will result in high-quality cured leaf coming out of the barn.

![]()

![]()