|

|

|

1. |

Crop and Pest

Management Field School

J.D. Green, Plant

and Soil Sciences

The Crop and Pest

Management Field School for private consultants, agribusiness

professionals, and producers is scheduled for June 30, 2005 from 8:30

am to 4:00 pm at the UK Agronomy Research Farm near Lexington,

Kentucky. Topics to be covered include: Herbicide Symptomology on

Grain & Horticultural Crops; Weed Identification; Insect Problems,

Identification, & Management; Corn Growth and Development Stages;

Soybean Production, Soybean Rust, & Other Foliar Diseases; and

Phosphorus Losses in Agricultural Soils.

Preregistration

of $10.00 is requested by June 17 to participate in this training

program. This educational training session has been approved for

Certified Crop Advisers CEU credits (3 hrs Pest Management, 2 hrs Crop

Management, and 1 hr Soil & Water). CEU credits for Pesticide

Applicator Training recertification have also been requested.

The UK Agronomy

Research Farm (Spindletop) is located at 3250 Ironworks Pike (Hwy

1973) on the north side of Lexington between Newtown Pike (Hwy 922)

and the Kentucky Horse Park. The preregistration form is linked at the

Agronomy Extension website:

http://www.uky.edu/Ag/Agronomy/Extension/.

return to top

|

|

2. |

Soybean Rust

on Volunteer Soybeans

Chad Lee,

Plant and Soil Sciences

Soybean Rust was

confirmed on volunteer soybeans in the southwestern Georgia on April

27, 2005. As soybean rust scouting continues, be sure to check in with

the University of Kentucky Soybean Rust website at: www.uky.edu/SoybeanRust.

This website contains all of the national links as well as information

specific to Kentucky. If you have questions or concerns regarding

soybean rust, be sure to contact your county agent.

return to top

|

|

3. |

Soybean

Production Practices for Soybean Rust

Jim Herbek and

Chad Lee, Plant and Soil Sciences

The potential

threat of soybean rust this year is on the minds of soybean producers.

In discussions with producers, some are considering a change in their

production practices because of the potential threat of this disease.

Most production

factors will not affect whether a field does or does not become

infected with soybean rust; however, a change in certain production

practices could reduce yield potential, even if soybean rust is not

present. The best management approach to this disease is to use

production practices that will maximize yield potential. If rust

occurs, the additional costs for fungicides will be a worthwhile

investment to protect that high yield potential.

Production

practice changes being considered by some producers are: soybean

varieties/maturity groups, planting date, row spacing, and plant

populations.

Soybean

Variety/Maturity Group.

Currently, there

are no varieties available with resistance to soybean rust and it will

be at least 5 to 10 years before resistant varieties are developed.

Therefore, select varieties with maximum yield potential, based on

performance tests, from maturity groups that are adapted to your area

or region. In Kentucky, adapted varieties include those from late MG

III, MG IV, and early MG V for various regions of the state.

While selecting

varieties from ultra-early maturity groups may possibly allow the crop

to avoid rust (assuming rust will come late in the season), the yield

potential of these unadapted maturity groups is reduced. Even without

soybean rust, their yield would be less than that of varieties from

adapted maturity groups.

Planting Date.

Plant

during the optimum planting period. Begin planting when soil

temperature is at least 60 to 65° F to promote rapid emergence and

uniform stands. This usually occurs from late April to early May in

Kentucky. Complete planting by early June to avoid a yield decline.

While extremely

early plantings before soil temperature reaches 60° F may allow the

crop to avoid rust (assuming rust will come late in the season),

planting date studies show no yield advantage (and often a yield loss)

for extremely early plantings over traditional planting dates. With

very early plantings, stand uniformity and plant vigor is often

reduced.

Spreading out

planting dates within the optimum planting period (along with some

variation in soybean variety maturity) is a good practice that would

result in differential stages of soybean development among your

fields. If soybean rust occurred, this would provide a better

opportunity (particularly with limited sprayer capacity) to spray

soybean acres in the time necessary to protect yield. Based on

experiences in Brazil, and unless our experience in the U.S. proves

otherwise, significant rust infection usually does not occur until R1

(beginning bloom) and fungicide applications prior to R1 are usually

not beneficial.

Row Spacing.

There

was a 12 to15% average yield advantage for narrow rows (15 inches or

less) in previous row spacing research at the University of Kentucky.

This yield advantage was greater in high yield environments and also

greater and more consistent in late (double-crop) plantings. The great

majority of soybeans are planted in narrow rows in Kentucky.

Some producers

are considering a switch back to 30-inch rows to better facilitate

equipment for late-season spray applications. The yield loss of

run-over rows from sprayer traffic (which will vary according to

sprayer boom width) in narrow row soybeans; however, will be much less

than the yield gained for using narrow rows. A good alternative, by

coordinating planter and sprayer size, is to establish skip-rows

(unplanted rows) in your narrow row system to facilitate wheel tracks

for late-season spray applications. The yield loss for unplanted rows

would be very minimal (or non-existent) with a slight savings in seed

costs.

Even without

soybean rust, wide rows would have a 5 to 6 bu/acre yield

disadvantage. If soybean rust occurs, the yield advantage for narrow

rows should more than compensate the cost of a fungicide application

to protect that yield gain.

Plant Population.

While

soybean populations most likely it will not have a significant impact

on rust, many farmers are using excessive seeding rates. Now may be a

good time to reduce seeding costs.

Studies have

shown that soybean plant populations as low as 100,000 plants per

acre, in many cases, yield as well as 200,000 plants per acre.

Reducing seeding rates to achieve final plant densities of 110,000 to

130,000 plants per acre would result in a seed cost savings of over

$10 per acre, particularly with higher priced seed. If soybean rust

occurs, the seed cost savings could be better invested in fungicides.

return to top

|

|

4. |

Control Seed

Costs to Manage Profit Margin

Sam McNeill,

Biosystems and Agricultural Engineering

Typical seed

costs on a per acre basis can vary between $40 to $70 for corn and $20

to $50 for soybean, depending on the desired plant population,

variety, seed quality and seed cost per bag. A spreadsheet tool has

been developed to help farmers and crop managers easily calculate

their actual costs and easily compare total costs for two seeding

rates for a number of different varieties.

By entering seed

tag data (weight per bag [for corn] or number of seeds per pound [for

soybeans], seed germination and purity) and a desired plant

population, the weight and number of seed per acre is calculated along

with the weight of seeds in a 200-ft planter calibration strip.

Enter the number

of acres for each variety and cost per bag of seed to compute the

number of bags needed for each variety, cost for each variety/seed lot

and per acre cost, as well as the total acres, number of bags and seed

cost for the grain enterprise and average cost per acre.

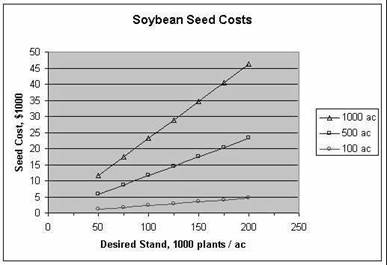

Figure 1 shows a

typical range in RR soybean seed costs at different plant populations

for 100, 500 and 1000 acre operations. Note that the cost difference

between desired stands is $23.16 per 1000 plants/100-acres for this

specific mix of seed quality and varieties.

Table 1

illustrates an example comparing soybean seed costs for 140,000 and

175,000 plants per acre for four different varieties on a 500 acre

farm. Note that the difference between these populations is a little

over $4050 or $8.10 per acre for the entire in this example. Growers

are encouraged to use this spreadsheet tool to help record and control

seed costs. It can be used to quickly calculate seed costs for other

scenarios with corn, soybean or wheat and is available on the web at

www.bae.uky.edu/ext/Grain_Storage/Calculators/.

Figure 1.

Typical range

in RR soybean seed costs at different plant populations for 100, 500

and 1000 acre operations.

|

Variety |

Lot |

No.

seeds

per

lb |

gm

per

1000

seeds |

Germ.

% |

Purity

% |

Table 1.

Illustration of the calculator for comparing soybean seed costs

for two different plant populations, based on seed tag/bag data

(seeds per pound, germination and purity) and the seed cost per

bag (50-lb unit). The number of acres for each variety is also

entered to calculate the total number of bags needed for each

population and the total and average seed cost. A calculation is

also made for a drill or planter calibration at both seeding rates

(weight and number of seeds per acre and weight of seed [grams] in

a 200-ft strip). |

|

SBxx1 |

BR-549 |

3500 |

129.6 |

90 |

98.0 |

|

SBxx2 |

BR-abc |

3000 |

151.2 |

85 |

98.0 |

|

SBxx3 |

BE-def |

3000 |

151.2 |

90 |

98.0 |

|

SBxx3 |

BR-xyz |

2500 |

181.4 |

90 |

98.0 |

|

Compare

seed costs at two different plant populations. |

|

|

|

|

Desired stand |

Row

Spacing

in |

Plants

per

ft |

lbs

seed

per acre |

actual

seeds

per

acre |

gm

per

200 ft

of row |

No.

acres |

No.

50 lb

bags |

Cost |

|

1000/ac |

plants/sq ft |

per

bag |

per

seed lot |

per

acre |

|

140 |

3.2 |

7.5 |

2.0 |

|

|

|

|

|

45 |

158,730 |

59 |

125 |

113 |

$28.00 |

$ 3,175

|

$ 25.40

|

|

|

|

|

|

56 |

168,067 |

73 |

125 |

140 |

$28.50 |

$ 3,992

|

$ 31.93

|

|

|

|

|

|

53 |

158,730 |

69 |

125 |

132 |

$30.00 |

$ 3,968

|

$ 31.75

|

|

|

|

|

|

63 |

158,730 |

83 |

125 |

159 |

$32.00 |

$ 5,079

|

$ 40.63

|

|

|

|

|

|

|

|

Total |

500 |

544 |

|

$ 16,214

|

$ 32.43

|

|

|

|

Desired stand |

Row

Spacing

in |

Plants

per

ft |

lbs

seed

per acre |

actual

seeds

per

acre |

gm

per

200 ft

of row |

No.

acres |

No.

50 lb

bags |

Cost |

|

1000/ac |

plants/sq ft |

per

bag |

per

seed lot |

per

acre |

|

175 |

4.0 |

7.5 |

2.5 |

|

|

|

|

|

57 |

198,413 |

74 |

125 |

142 |

$28.00

|

$ 3,968

|

$ 31.75

|

|

|

|

|

|

70 |

210,084 |

91 |

125 |

175 |

$28.50

|

$ 4,989

|

$ 39.92

|

|

|

|

|

|

66 |

198,413 |

86 |

125 |

165 |

$30.00

|

$ 4,960

|

$ 39.68

|

|

|

|

|

|

79 |

198,413 |

103 |

125 |

198 |

$32.00

|

$ 6,349

|

$ 50.79

|

|

|

|

|

|

|

|

Total |

500 |

681 |

|

$ 20,267

|

$ 40.53

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

return to top

|

|

5. |

Predicting

Soybean First Flowering Date

Chad D. Lee,

Dennis B. Egli and James H. Herbek, Plant and Soil Sciences

Soybean first

flowering date appears to be a critical time for managing Asian

Soybean Rust. Observations from Brazil indicate that soybean rust does

not infect soybeans until sometime at or after first flowering, even

when spores are present at earlier soybean growth stages. Based on the

observations from Brazil, we expect most soybean rust infections to

occur sometime after first flowering in the United States. As a

result, we would expect most fungicide applications to occur sometime

after first flowering.

A crop simulation

model (CROPGRO-soybean) was used to predict when soybeans will first

flower in Kentucky. Weather data from the University of Kentucky

Spindletop Farm was used as input, and first predicted flowering dates

were compared with measured dates from several experiments to be sure

that the model was accurate.

Flowering date

will vary year to year, depending on weather conditions. The variation

for first flowering date is greater for soybeans planted early than

for soybeans planted late. As a result, we recommend that farmers and

field scouts begin checking fields ten days prior to the predicted

first flowering dates in Table 1.

The predicted

first flowering dates can be adjusted depending on relative maturity

of a soybean variety and location of the field. Soybean varieties in

the early part of a maturity group category (such as a 4.1 relative

maturity in Maturity Group IV) will likely reach first flowering a few

days earlier than the predicted date, while soybean varieties in the

later part of the maturity group category will likely reach first

flowering date a few days after the predicted date.

Flowering depends

on both daylength and temperature, so the predicted dates may occur

slightly earlier in western Kentucky where temperatures are

historically slightly warmer. Farmers in western Kentucky and the two

southern tiers of counties may want to adjust the predicted first

flowering dates ahead two or three days from those presented in the

tables.

More information

on predicting soybean flowering dates is available in AGR-184:

Predicting Soybean First Flowering Date, a new Extension

publication. This new publication is available online at www.uky.edu/Ag/GrainCrops/

and is available at any Kentucky County Extension Office.

Table 1.

Predicted

first flowering date for different maturity groups and planting dates

in Kentucky.

|

|

|

Soybean

Maturity Group |

|

|

|

Planting

|

MG II |

MG III |

MG IV |

MG V |

|

|

|

Date |

Predicted

First Flowering Date |

|

|

|

|

mean1 |

SD2 |

mean |

SD |

mean |

SD |

mean |

SD |

|

|

|

|

|

(±) |

|

(±) |

|

(±) |

|

(±) |

|

|

|

May 1 |

June 3 |

2 |

June 8 |

4 |

June 17 |

4 |

June 25 |

5 |

|

|

|

May 15 |

June 15 |

2 |

June 21 |

2 |

June 29 |

3 |

July 8 |

3 |

|

|

|

May 29 |

June 27 |

2 |

July 5 |

1 |

July 12 |

1 |

July 19 |

2 |

|

|

|

June 12 |

July 10 |

1 |

July 16 |

1 |

July 23 |

1 |

July 29 |

1 |

|

|

|

June 26 |

July 24 |

1 |

July 29

|

1 |

Aug 2 |

1 |

Aug 8 |

1 |

|

1.

Average flowering date for 29 years of weather data.

2.

Standard deviation.

return to top

|

|

6. |

Northern Corn

Leaf Blight, Planning for 2005

Paul Vincelli,

Plant Pathology

Northern leaf

blight (NLB) was more severe in Kentucky in 2004 than in any year

since the early 1990s. The cool, wet, cloudy weather that prevailed

during most of the 2004 season in many areas played a major role in

disease development. Wet weather with temperatures in the range of 64

to 81oF favors infection and spore production by the fungus

that causes NLB (called Setosphaeria turcica, but also known as

Exserohilum turcicum and Helminthosporium turcicum).

Furthermore, the extended cloud cover makes plants from a susceptible

corn hybrid even more susceptible to the disease.

Although unusual

weather was only part of the picture, my concern is that there are

some indications of a possible trend of increasing pressure from NLB.

Records from the UK Plant Diagnostic Laboratories indicate that this

disease has increased over the past four to five years. A respected

and highly experienced corn pathologist from a neighboring, major

corn-producing state reported similar observations to me. The weather

in 2004 certainly played a role in the severe outbreaks observed, as

explained above.

At this time we

don’t know the complete reason for the apparent increased severity of

NLB over the past several years. It could be due to a new race of the

fungus or it could be due to an unintended decline of partial

resistance in the currently available hybrids to NLB as breeders have

focused on other priorities. It may simply be due to prevailing

weather patterns. This issue is currently being researched by

pathologists in the Midwest; I’ll know more in a few months.

Some Biology of

NLB.

Symptoms of NLB are elliptical, grayish-green or tan lesions 1 to 6

inches long with smooth margins. The large ones are typical for a

susceptible hybrid growing under cool, cloudy, wet conditions. During

damp weather, greenish-black fungal sporulation is produced in

lesions. Older leaves are affected first. Severely affected leaves can

be killed when lesions join together.

The S. turcica

fungus survives in undecomposed corn residue. Spores are spread by air

currents. Severe yield loss can occur when upper leaves become

blighted during early grain fill. Strains of the fungus also infect

sorghum, johnsongrass, and sudangrass, although strains that attack

these plants do not attack corn.

Factors That Can

Favor NLB Development

1. Cool, wet,

cloudy weather, as mentioned above.

2. Reduced

tillage, since the fungus survives in undecomposed leaves of diseased

corn.

3. Continuous

corn, which favors a buildup of inoculum by repeatedly planting a

host.

4. Substantial

late-season growth of volunteer corn after harvest (often occurs after

an early harvest followed by mild temperatures).

5. Late-planted

crops can be exposed at a relatively young age to spore clouds coming

from earlier-planted crops, resulting in more yield loss than in an

earlier crop.

6. Irrigation,

since this provides the humidity and leaf wetness that favors the

disease.

Management.

Producers should be aware of the level of susceptibility to NLB for

all hybrids planted in 2005, but especially in or near fields under

conservation tillage where NLB occurred this past season. Recent

studies by Dr. Pat Lipps from The Ohio State University suggest that

the levels of partial resistance among many, perhaps the majority, of

hybrids without Ht genes is quite low. Work continues on the

question of how much partial resistance exists in the corn hybrids on

the market, but the data from Dr. Lipps certainly raise flags, given

the high inoculum levels that are now present on many farms.

The law of

averages suggests that 2005 season is not likely to be as cool,

cloudy, and wet as this past season, in which case many producers

would “dodge a bullet”. However, with the high inoculum levels that

are present in certain areas, especially in western Kentucky, a

repeat of the same kind of weather could result in destructive

epidemics on susceptible varieties in some localities.

There are two

types of resistance to NLB: complete resistance (more or less) and

partial resistance. In hybrids with partial resistance, fewer lesions

form and they are smaller and with less sporulation than on a

susceptible hybrid.

In hybrids with

(nearly) complete resistance, lesions which form are yellow and

limited in size, and sporulation by the fungus is very limited. These

are hybrids with one or more Ht genes. For example, on hybrids

carrying an Ht1, Ht2, or Ht3

resistance gene, long, yellow to tan lesions with wavy margins and no

sporulation are observed on leaves infected with S. turcica.

These lesions are a resistance reaction and can be easily confused

with Stewart's wilt. The HtN gene results in lesions that are

necrotic, but these lesions are smaller and much delayed compared to

lesions on susceptible hybrids. More commonly, corn hybrids have

partial resistance. In that case, NLB can still develop on the hybrid

but it usually does so more slowly that on a fully susceptible

variety.

Under many

circumstances, a moderate to high level of partial resistance would be

sufficient to control the disease. However, when exposed to high or

very high disease pressure, a hybrid with complete resistance would

often outyield a partially resistant hybrid. Consider the factors

discussed in the preceding section to decide which fields might need a

substantial level of resistance to NLB in 2005.

Conclusion.

While

sowing fear is not my usual educational style, I am very concerned

about the potential risk for serious damage from NLB in 2005. The key

here is that this is potential risk, since we don’t know if the

weather will favor disease development. In the meantime, I encourage

producers to pay close attention to the level of NLB resistance in the

hybrids they choose, especially for late plantings and particularly

for use in or near fields that had serious damage this past season.

Thanks to Bill

Meacham of Pioneer Hi-Bred for observations of the association of

volunteer corn with NLB.

return to top

|

|

7. |

Fungicides for

Use Against Northern Leaf Blight

Paul Vincelli,

Plant Pathology

Since corn

hybrids have been selected and much corn has been planted, there are

some management options should epidemics of northern leaf blight (NLB,

caused by the fungus Setosphaeria turcica) occur in 2005.

Inoculum levels are high in many fields, and if sustained periods of

unusually cool, wet weather occur, which would favor the development

of NLB, we could see very damaging outbreaks in fields without

adequate resistance.

If a combination

of crop rotation and hybrids with moderate to high NLB resistance were

selected, then there should be no reason to spray a fungicide.

However, there could be isolated instances where the producer may see

a benefit to the application of a fungicide. For example, imagine a

field sown to a susceptible hybrid that has a 180+ bushel/acre yield

potential within two weeks on either side of tasseling. If that field

is showing large (3-6 inches) lesions indicative of a susceptible

reaction of NLB on or above the ear leaf, and the long-term forecast

calls for continued cool, wet weather, it may be worthwhile to protect

the high yield potential by applying a fungicide. Such cases would be

few in number, but they may occur, depending on the weather.

Fungicide

Options.

There are several

fungicides labeled for use against NLB. Based on the research I have

seen, the most effective against this disease is Quadris Flowable®. If

applied once at 9.2 to 15.4 fl oz/acre rate, a producer would pay

about $21.56 to $36.09 for the product and $7.50 to $8.00 per acre for

aerial application (assumes a product price of $300/gal). Be aware

that the label requires a minimum application volume of 5 gal/acre in

grain crops. I’ve seen indications of yield losses of anywhere from 5

bu/acre to 50 bu/acre from NLB on susceptible and moderately

susceptible hybrids during the 2004 season. Given the above cost

estimates for applying Quadris7,

one would have to avert a yield loss of at least 14 to 21 bu/acre to

break even for the costs of applying fungicide (assuming a $2.25 /bu

crop value). Quadris has a seven-day pre-harvest interval for field

corn.

Tilt® (or

PropiMaxEC®), which has the same active ingredient) also can be

applied for control of NLB, but in the research I have seen indicates

that Tilt is not consistently as effective as Quadris. When applied

once at 2to 4 fl oz/acre, a producer would pay $5.59-11.19 /acre for

the Tilt7

and $7.50 to 8.00 for application costs (assumes a product price of

$358/gal). Like Quadris, Tilt has a restriction of a minimum of 5

gal/acre when applied aerially. Other important label restrictions

include: (1) Tilt may not be applied after silking, and (2) there is a

30-day pre-harvest interval in field corn.

Stratego®, a

pre-mix of propiconazole and trifloxystrobin, is labeled also for NLB

control. I am aware of only one 6-year old field test evaluating the

performance of Stratego specifically for NLB control, and that test

does not include rates on the current label. Therefore, I can’t make a

definitive statement about its relative efficacy against this disease.

When applied at 10 to 12 fl oz/A, a producer would pay $11.72

to14.06/acre for the Tilt and $7.50 to 8.00 for application costs

(assumes a product price of $150/gal). Among several restrictions

indicated on the label is the prohibition against application to field

corn after silking.

Products

containing chlorothalonil (Bravo®, for example) or mancozeb (Dithane®,

etc) are labeled for NLB control. However, research shows these

contact fungicides are not as effective as either systemic fungicide

listed above. Furthermore, it seems likely that the incomplete

coverage of leaf surfaces that one expects with aerial applications

would be a serious limitation for these two contact fungicides.

Note that for

several of these fungicides, the disease is called “Helminthosporium

leaf blight” caused by Helminthosporium turcicum, an old name

for the fungus that causes NLB.

Potential

Benefits of Fungicide Application in Limited Instances.

In the situation

of high disease pressure described above, one would probably at least

recoup the cost of a fungicide application, and exceed it in some

instances. In addition to protection of yield, if NLB is “brewing” in

a susceptible hybrid, a fungicide application could help protect test

weight and stalk quality. When leaves are blighted during grain fill,

the corn plant draws reserves out of the stalk in order to fill the

grain. This results in weak stalks susceptible to lodging. Thus, some

producers may feel a fungicide treatment is justified on the basis of

retention of stalk quality. The application might allow the producer

to let the crop dry down for a time in the field, instead of having to

rush in to harvest at black layer and dry the corn down from 30 to 35%

moisture concentration, resulting in less flexibility in scheduling

harvests, higher drying costs, and increased risk of stress cracks

from drying operations.

There are no

simple answers as to whether a fungicide application will be worth

applying. So much depends on complex factors that are often

unpredictable. However, perhaps these comments will help producers

think through some of the ramifications of applying a fungicide if

faced with a NLB outbreak this year.

return to top

|

|

8. |

Resistance

Management Grouping Codes Now Appearing on Some Pesticide Labels

Ric Bessin, Kenny

Seebold, Doug Johnson, and Lee Townsend,

Entomology and

Plant Pathology

In an effort to

make management of pesticide resistance easier for pesticide users,

some companies have begun to place mode-of-action classification codes

on the front of their pesticide labels. These designations appear as a

three part box, as in the examples below:

|

GROUP |

1B |

INSECTICIDE |

or |

GROUP |

11 |

FUNGICIDE |

These

classification schemes for insecticides and fungicides provide growers

with an easy to recognize numerical group for a particular pesticide

based on its mode of action. Pesticide products with multiple modes of

action will multiple classifications listed. These numerical schemes

should make identifying pesticides with the same modes of action

simpler and should help pesticide avoid the overuse of a single class

of pesticide.

Generally, the

more frequently a grower sprays the same mode of action to control a

pest problem, the more quickly a pest is likely to develop resistance.

Many factors affect the rate of pesticide resistance development and

most of those are out of our control (development rate of the pest,

migration rate from susceptible populations, background levels of

resistance), but we can control judicious use of pesticides and

rotation of chemicals with different modes of action when repeated

applications are needed.

Keys to using

this system correctly:

v

Read and recognize the numerical groups on the pesticide labels. Those

with different designations have different modes of action.

v

To

delay and/or prevent the development of resistance by pests, growers

must avoid the repeated use of the same mode of action. Users need to

alternate different pesticide classes periodically when repeated

sprays are needed. Alternate products from different numerical groups

for repeated applications.

v

Do

not tank mix to pesticides from the same numerical group (same mode of

action).

v

As

always, only use pesticides at labeled rates and according to labeled

spray intervals.

Other factors

that delay the development of pesticide resistance:

v

Always time pesticide sprays when they will do the most good. Most

pests have a stage when they are most vulnerable. Don’t wait too long

to begin applications of pesticides. In the case of fungicides,

“rescue” applications of chemicals to severely diseased fields can

lead to the development of resistance in pathogen populations (more of

the pathogen population is exposed to the fungicide and therefore the

odds of selecting for resistant individuals go up).

v

Take an integrated approach to pest control and maximize the utility

of proper cultural controls, crop rotation, resistant varieties, and

natural enemies of pests.

v

Use

pest and weather monitoring and economic thresholds as guides when

making decisions to make pesticide applications.

v

Try

to preserve natural enemies of pests through the use of selective

pesticides or targeted applications.

v

Mix

and apply pesticides carefully to ensure correct dosage and coverage.

Sprayers must be calibrated regularly to account for nozzle wear. Use

the proper spray volumes and pressure to ensure adequate coverage.

v

Eliminate crop residues after harvest when practical to remove

overwintering sites for pests.

return to top

|

|

9. |

Corkscrew Corn

Chad Lee, Plant

and Soil Sciences

Reports have come

in of twisted or corkscrewed and horizontal corn seedlings beneath the

soil surface. For normal seedlings, the white portion of the shoot

which comprises the mesocotyl and coleoptile grows nearly straight

upward toward the soil surface. For corkscrew and horizontal

seedlings, the shoot does not grow straight to the soil surface but

resembles a corkscrew or remains horizontal under the soil surface

(Figures 1 and 2). In some instances, the seedling will not make it

through the soil surface and leaves could unroll underground. There

are several factors that may cause twisted or horizontal shoots.

|

Cool

Weather.

Soil temperatures

less than 55 degrees Fahrenheit for an extended period or rapid

changes in temperatures, such as air temperatures in the 80s and

dropping below 55, can cause the twisting. Seed that imbibes water as

cold as 50 degrees Fahrenheit can go through imbibitional cooling,

which can result in corkscrewing. If the coleoptile has already

emerged from the seed, then I speculate that as the coleoptile grows

toward the soil surface until it comes into contact with the cool

temperatures and starts to grow down, then back up and then down again

causing the corkscrewing effect.

Soil Compaction.

Restrictions in the soil around the germinating seed can cause the

mesocotyl and/or coleoptile to grow around the restriction zone.

Sidewall compaction, heavy rains immediately following planting, and

soil clods can all cause restriction zones that result in the twisting

appearance.

Herbicides.

Soil-applied herbicides that are seedling shoot inhibitors (containing

one of the following active ingredients: alachlor, acetochlor,

metolachlor, dimethenamid, or flufenacet) in combination with cool,

wet weather and crusted soils can disrupt proper growth of the shoot.

Since most of these herbicide products are formulated with a safener,

herbicide injury from these products at proper use rates is extremely

rare. However, the cooler temperatures can slow corn growth and

increase herbicide injury. Factors inhibiting or slowing shoot growth,

such as those mentioned above, are usually required before herbicide

injury occurs at proper use rates.

Kernel Position

in the Soil.

As the mesocotyl

elongates, the coleoptile emerges from the embryo side of the seed and

grows toward the dent end of the kernel. If the embryo side is facing

down, then the coleoptile will grow along the kernel until it grows

past the dent end of the kernel. At this point, the coleoptile will

begin growing upward. In greenhouse studies, shoots from kernels with

the embryo facing down require about one more day to emerge then

shoots from kernels with embryos facing up. I would expect cooler

temperatures and soil compaction to delay emergence even more.

Seeing the Light.

Seedlings that manage to “spike” through the soil surface and leaf out

above ground will likely recover from the corkscrew symptoms and

produce an acceptable yield. However, continued cool temperatures and

cloudy skies will slow seedling growth and could limit the amount of

recovery. The cool temperatures and cloudy skies not only slow corn

growth but also favor seedling diseases and insects. Field scouting is

necessary to determine the crop condition and to make management

decisions accordingly.

Sources:

v

Loux, M. 2004. Causes of leafout and underground leaf emergence in

corn. C.O.R.N Newsletter 2005-10, April 25, 2005 - May 3, 2005, The

Ohio State University. URL: http://corn.osu.edu/

v

Nielsen, R.L. 2004.Corkscrewed Corn Seedlings. Corny News Network,

Purdue University. URL: http://www.kingcorn.org/news/articles.04/Corkscrew-0501.html

v

Saab, I. 2005. Stress Emergence in Corn. Crop Insights. vol. 5, no. 6.

Pioneer Hi-Bred International.

return to top

Newsletter Home

Printer Friendly Version (pdf)

|

|

|