Kentucky Pesticide Safety Education Program

Questions?

Contact

Dr. Ric Bessin

Dept. of Entomology

University of Kentucky

859-257-7450

rbessin@email.uky.edu

Factors Affecting Pesticide Drift

Drift is the uncontrolled movement of a pesticide away from its target area. They main types are particle drift and vapor drift.

Drift can

- damage susceptible off-target sites (plants, animals, etc.)

- reduce pest control, which wastes pesticide and money, and

- contaminate the environment: water pollution and illegal pesticide residues.

This can mean lawsuits, administrative action, or criminal fines. Be able to recognize situations that increase potential problems and know how to deal with them.

Particle Drift

Particle drift occurs when spray droplets physically move away from the target site during application.

The main causes of particle drift are:

- environmental factors: wind speed above 10 mph, low humidity, or high temperature

- improper spray practices

- equipment problems.

Droplet Size

Droplet size is one of the most important factors that affect particle drift. High sprayer pressure or nozzles that produce fine droplets that cover the target uniformly and completely. However, they can drift long distances.

[return]

Spray Pressure

Changes in operating pressure cannot be used safely to make major changes in sprayer output. Doubling the spray pressure (for example, from 20 psi to 40 psi) does not double the flow rate. You must increase the pressure four times (20 psi to 80 psi) to double the flow rate.

Exceeding the recommended pressure range often results in more drift potential. This increase in pressure would produce more fine spray particles, increasing the potential for spray drift.

To obtain a uniform spray pattern and to minimize drift, keep the operating pressure within the recommended range for each nozzle tip. To maintain a proper spray pattern, adjust nozzles according to the manufacturer's recommendations on nozzle spacing and spray angle.

Lower pressure and coarse nozzles produce large droplets. The drift potential is lower but coverage is not as good.

Ideal spray droplet size depends upon the type of pesticide being applied. Contact pesticides usually require smaller droplet size to be most effective. Larger droplet size may be more effective for systemic pesticides.

Ideal spray droplet size depends upon the type of pesticide being applied. Contact pesticides usually require smaller droplet size to be most effective. Larger droplet size may be more effective for systemic pesticides.

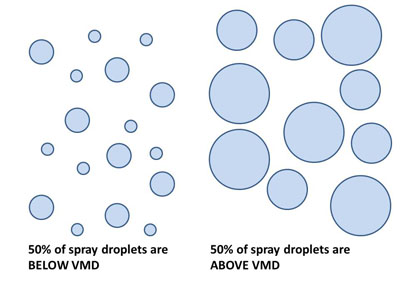

Spray nozzles produce droplets of many sizes. The average droplet size from a specific nozzle is its volume mean diameter (VMD). The unit is a micron (1/25,400 inch). If a nozzle output has a VMD of 300 (droplets of very fine rain) microns, 50% of the spray volume is in droplets that are less than 300 microns and 50% are above 300 microns.

Temperature and humidity affect evaporation of spray droplets. High temperature and low humidity results in faster evaporation, droplets get smaller. The smaller droplets are moved farther by winds.

[return]

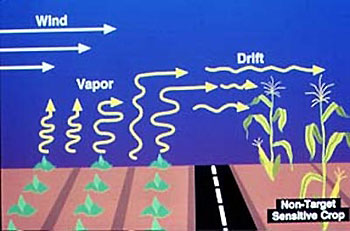

Vapor Drift

Vapor drift occurs when a pesticide evaporates and moves in the air as a gas. This is most likely to occur when the temperature is above 85° F.

Vapor drift can happen for several days after application. The best way to prevent vapor drift is to read, understand, and follow label directions. Avoid using volatile herbicides near or upwind of sensitive crops.

An example vapor drift warning statement would be:

Avoid application when temperatures may exceed 85° F

during or 24 hours following the application.

[return]

Preventing Pesticide Drift

Studies have shown that a sizable percentage of pesticides may never reach the intended target site because of drift. Significant drift can damage or contaminate sensitive crops, poison bees, pose health risks to humans and animals, and/or contaminate nearby soil and water. It is impossible to eliminate drift, but it is possible to reduce it to a tolerable level.

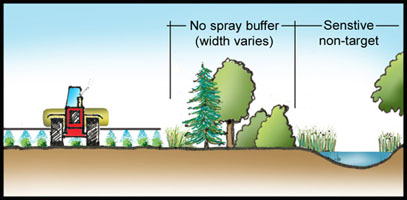

To reduce chances for drift:

- Spray when the wind speed is between 3 and 10 miles per hour.

- Spray downwind from sensitive areas, such as houses, schools, sensitive crops, waterways, or beehives.

- Use proper nozzles and pressures.

- Use drift control additives (if appropriate).

- Lower boom height.

- Leave an untreated border or buffer area in the downwind target area.

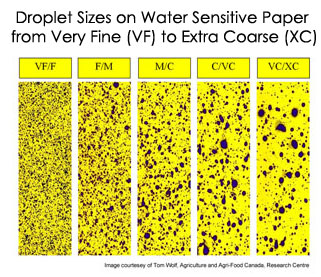

Droplet Size

A droplet size classification system describes the droplet sizes produced by a nozzle. This standard system classifies nozzles into eight categories (see table below). You can use them to select a nozzle, orifice size, and operating pressure that produces a label recommended droplet size spectrum. Consult the label for the droplet size specifications that may be in place for a particular application.

| Standard Spray Droplet Spectrum Categories | ||

|---|---|---|

| Droplet Category | Symbol | Color Code |

| Extra fine | XF | Purple |

| Very fine | VF | Red |

| Fine | F | Orange |

| Medium | M | Yellow |

| Coarse | C | Blue |

| Very coarse | VC | Green |

| Extra coarse | XC | White |

| Ultra coarse | UC | Black |

Other Factors

Drift control additives are a specific type of chemical adjuvant. They must be mixed and applied according to label directions to be effective. Research has shown that some products intended to reduce drift in fact increase drift potential. Although some of these additives dramatically increase droplet size, they may also reduce coverage and lessen the overall effectiveness of the pesticide. Thoroughly evaluate drift control additives before using them.

Wind speed and direction are the most important environmental factors influencing spray drift. Labels may indicate maximum and minimum wind speeds for application. Except in the case of temperature inversions (see below), early morning and evening often are the best times to apply pesticides. Windy conditions are more likely to occur around midday, when the temperature near the ground increases. This causes hot air to rise quickly and mix rapidly with the cooler air above it, favoring drift.

The best time to spray is when spray droplets move slowly upward in the absence of windy or inversion conditions. Low relative humidity and/or high temperatures also can increase the potential for spray drift. Under these conditions, water evaporates more rapidly, producing smaller spray droplets that drift more easily. Avoid spraying during these times.

Nozzle height above the ground or target affects drift. The general rule of thumb is 1:1 - the space between nozzles should be the same as the boom height. Applications that use large droplets released close to the ground often produce little drift. Drift from boom sprayers can be reduced by lowering the boom height. However, lowering the boom can change the coverage pattern significantly.

The higher the boom, the greater the chance for drift.

Pesticide labels may provide more specific instructions to reduce drift. The EPA works with pesticide manufacturers through the registration and registration review programs to provide more detailed information about factors that significantly affect spray drift.

Instructions can include:

- Spray droplet size categories

- Spray release heights

- Minimum and maximum wind speeds

- Buffer zones, if necessary

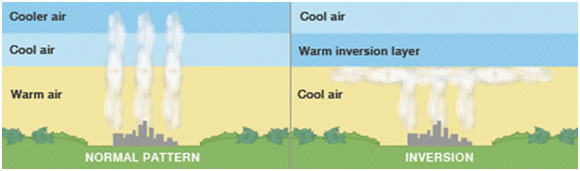

Wind Speed and Temperature Inversions

Applications made under low-wind conditions can sometimes produce more extensive drift than under high winds. Drift that occurs over long distances (more than a mile) is most often the result of applications made during a temperature inversion. This exists when the air at ground level is cooler than the air above it. Under these conditions, the air is considered stable because there is little or no vertical air movement.

Almost all air movement during an inversion is sideways. This causes a high concentration of small spray droplets to be suspended in this layer of cool air near the ground. These droplets can then be carried long distances, especially if wind speeds increase. When the spray droplets settle, they may still be concentrated enough to cause damage or harm. Inversions may occur at any time of the day and at any height above the ground. However, they most often develop during the early evening hours as the ground temperature begins to cool and the warm air has already risen.

Movement of spray droplets or particles during normal and inversion conditions

You can recognize these stable air conditions (inversions) by observing the movement of dust or smoke. If dust or smoke rises little from its source and tends to hang in the air, an inversion may be present or developing. Do not apply pesticides under such conditions.

Whenever possible, choose a pesticide formulated as a low-volatility product. Do not apply volatile pesticides on hot days. Some products may even volatilize several hours after application so beware if high temperatures are predicted for later in the day. Many labels advise against applying these products when temperatures are at or above 85°F. Remember to check label precautions for product-specific concerns about vapor drift.

| Drift Reduction Technique | Explanation |

|---|---|

| Follow drift reduction instructions on the product label | Read the label and reference guide to learn proper nozzle and pressure combinations. |

| Select a nozzle to increas droplet size | Use the largest droplets that provide necessary coverage. |

| Look at new technologies | Air-induction and venturi nozzles may help reduce drift. |

| Lower sprayer height if possible | The higher the nozzle above the target, the greater the potential for drift. |

| Use appropriate travel speed | High travel speeds may result in a bouncing boom. |

| Be aware of wind speed and direction and nearby sensitive areas | More spray volume moves off-target as wind increases or direction changes. Wind currents can drastically affect spray droplet deposition. |

| Use buffer zones/no-spray zones near sensitive areas | Leave a buffer/no-spray zone if sensitive areas are downwind. |

| Do not spray during a temperature inversion | Temperature inversions prevent the dissipation of spray particles. |

| Use a drift-control additive when needed | Drift-control additives increase the average droplet size produced by the nozzles but they do not make up for poor spraying practices. |

[return]

Applicator Responsibilities

Applicators are legally responsible for any damages resulting from the off-target movement of pesticides. Assess the vulnerability of neighboring properties and those areas downwind of the application site. Evaluate weather conditions for temperature inversions, wind direction, and wind speed before making the all-important decision about whether to spray. You may have to adjust your application equipment to reduce spray drift. Consider using low-volatile formulations or adding a drift control agent or thickener to help minimize drift.

A good drift management program includes a combination of all drift reducing techniques available for a particular application. Ensure that:

- Pesticides do not move beyond the target site.

- All people and animals are kept out of the treatment area according to label instructions.

Using approved application techniques and adopting new technologies designed to reduce spray drift can improve the performance of spray mixes, benefit the environment, and be more cost-effective. Any one practice used alone may not sufficiently reduce drift. Use as many drift-reduction techniques as practical when spraying.

Some symptoms of phytotoxicity from herbicide drift:

- Death of seedlings

- Death of rapidly growing succulent tissues

- Stunting or delayed plant development

- Misshaped or distorted plants, fruits, or leaves

- Dead spots or flecks on leaves

- Dead leaf tips or leaf margins

- Dead areas between the veins of the leaves

[return]

Chemical Trespass and Involuntary Exposure

Chemical trespass means that chemicals have moved from the target area onto someone else's property. This creates the potential for involuntary exposure and concern about pesticide residues on a neighboring lawn, garden, or child's or pet's play area. Take steps to avoid drift, such as leaving untreated buffer areas and being aware of wind speed and direction. Take every precaution to avoid drift or accidental overspray.

[return]

Pesticide Persistence or Carryover

Pesticides vary greatly in their persistence carryover or persistence in soil. Carryover can affect rotational crops by causing reduced germination, injury, or illegal residues.

Carryover injury usually is due to:

- the pesticide type and rate that was used,

- sensitivity of the rotational crop, and/or

- environmental factors that reduce normal pesticide breakdown.

Preventing Carryover Problems

- Follow label restrictions for rotational crops.

- Use the rate recommended for the soil type. Do not use more than is needed for adequate control.

- Apply products accurately. Be sure all nozzles are calibrated and operating properly.

- Turn the sprayer off at the end of the field to avoid overlaps at end rows.

[return]

1) High humidity conditions _________ the volatility of a pesticide.

2) Studies have shown that almost all pesticides reach their target site during an application.

3)Which symbol represents the nozzle that produces the largest droplet size?

4) Drift is the movement of a pesticide from the application site by ____________.

5) Doubling the pump pressure will double the nozzle output.

6) You can reduce pesticide spray drift by ___________.

7) Changing to nozzles with larger openings and decreasing sprayer pressure will result in the production of smaller spray droplets.

8) A spray additive that makes the spray liquid thicker produces _______ spray droplets.

9) All formulations of the same active ingredient have the same risk of volatility.

10) ______________ are the most important environmental factors influencing spray drift.

- wind speed and direction

- wind direction and relative humidity

- wind speed and UV intensity

- wind direction and relative humidity

11) Windy conditions are more likely to occur around __________.

12) The distance between nozzles should be _______ the boom height.

13) The best time to spray is when conditions cause spray droplets to __________.

14) Low relative humidity and /or high temperatures __________ the potential for spray drift.

15) Drift from boom sprayers can be decreased by raising the boom from 20 inches to 36 inches above the target

16) Reduce chances of drift by spraying when the wind speed is __________.

17) In general, the distance from a nozzle tip to its target (crop or ground) should be twice (2x) the nozzle spacing.

18) Temperature inversions, which can increase drift, occur when ground level air is _________ the air above it.

19) Most all air movement during an inversion is _________.

20) The ________ is legally responsible for any damages resulting from the off-target movement of pesticides.

21) Pesticides that change readily from a liquid to a gas are considered to be __________.

22) In order to reduce the chances of vapor drift, the labels of volatile pesticides advise against apply the products when air temperatures are at or above ____°F.

23) Chemical trespass means that _______________ .

- some one entered a sprayed field too early

- an unauthorized person entered a chemical storage area

- chemicals moved from the target area onto someone else's property

2) Phytotoxicity can appear as _________.

25) Most phytotoxicity to non-target plants is the result of ________.

Image credits: Pesticide movement in the environment | Point and non-point sources of pollution |Spray droplet movement during Inversions | Vapor drift | Karst topography map

website designed by P.M. Dillon copyright © 2015 University of Kentucky Department of Entomology

University of Kentucky College of Agriculture |

S-225 Agricultural Science Center North, Lexington, KY 40546-0091 | 859.257.7450

An Equal Opportunity University |

Last modified

<

11/30/2018