Kentucky Pesticide Safety Education Program

Questions?

Contact

Dr. Ric Bessin

Dept. of Entomology

University of Kentucky

859-257-7450

rbessin@email.uky.edu

The application method you choose depends on such factors as the nature and habits of the target pest, characteristics of the target site, and properties of the pesticide formulation. You also must consider the suitability of the application equipment, cost, and efficiency of alternative methods.

Here are some common pesticide application methods:

|

Band -applied along fence rows or borders, often with a non-selective herbicide to kill all vegetation. |

|

Broadcast-the pesticide is uniformly applied over a large area of turfgrass on foot or with motorized equipment. |

|

Drench applications are used to treat specific areas usually with systemic products that are taken up by the root system and moved throughout the plant. |

|

Foliar -directed to the leafy portions of a plant. |

|

Soil -placed directly on or in the soil instead of on a growing plant. |

|

Space treatment-applied in an enclosed area. |

|

Spot treatment-is an efficient way to treat specific problem areas without treating the entire turf area. Be careful to not walk through sprayed areas when using non-selective herbicides like glyphosate and watch for dripping from the nozzle while walking from site to site to treat. |

|

Wiper applicator-can be used to wipe a non-selective herbicide (glyphosate) to selectively kill individual weeds.The wiper's wetness must be less than dripping and handled carefully to avoid accidentally treating desired plants. |

[return]

Safety Systems

Pesticide Containment Pad

If you often store, handle, mix and load pesticides, or clean equipment at the same location, you may have to install a pesticide containment pad. Check EPA and Kentucky state regulations to determine when a containment pad is required. These pads are designed to contain spills, leaks, overflows, and wastewater for reuse by the applicator or for disposal by a commercial waste management contractor. They make it easier to clean up spills and help to prevent environmental contamination.

Impervious containment pad

Generally, the containment pad must be made of impermeable material. It should be concave or have curbs, berms, or walls high enough to hold the largest amount of spill, leak, or equipment wash water likely to occur at the site. It also must have a system to remove and recover spilled, leaked, or released material by either an automatic sump system or a manually operated pump. Smaller, portable pads and lightweight trays made of heavy-duty plastic may be used when mixing and loading at the application site.

[return]

Hydraulic Sprayers

The application equipment or device must be able to apply the pesticide to the intended target at the proper rate. The label specifies the legal application rate and may suggest the appropriate equipment for use with the product.

Hydraulic sprayers range from powered units with a multiple-nozzle boom to a hand-pumped backpack sprayer. In all cases, pressure from either a pump or compressed gas or air is used to atomize the spray mix at the nozzle. High pressure pumps are needed to provide good spray coverage on large trees. Manual sprayers are designed for spot treatments and for areas unsuitable for larger units. They are relatively inexpensive, simple to operate and maneuver, and easy to clean and store. Adjustable spray guns are often used for lawn care sprays.

Sprayer Components

Tank

A tank is necessary to contain the spray mix. Choose one made of, or coated with, a material that does not corrode and that can be cleaned easily. Cleaning prevents accumulations of corrosion and dirt that clog screens and nozzles, increasing wear on the equipment. Large tanks require an opening in the bottom to aid in cleaning and draining. A large top opening is useful for filling, cleaning, and inspecting the tank. The opening must have a watertight cover to prevent spills. A tank agitation system/device is useful for most sprayable formulations, especially for wettable powders or dry flowables. Constant mixing of a pesticide and liquid carrier produces a uniform spray mixture (suspension) and results in an even application of the chemical.

Exposure to sunlight and corrosive chemicals can shorten the life of polyethylene tanks.

Three common signs of wear and potential tank failure are:

- Scratches are on the surface and can be seen and felt

- Crazing is a network of fine lines or cracks that may look like a patchwork, but often cannot be seen with a visual inspection. Crazing can be seen when using one of the testing methods explained below. Crazing occurs within the tank wall and can be a sign of deterioration of the plastic, which may lead to cracks. Tanks that show signs of crazing will still hold liquids, but the integrity of the tank is questionable. For this reason, caution should be used when putting any hazardous substance in tanks that show crazing.(Photo: omafra.gov.ca)

- Cracks extend through the plastic wall and can be visually seen and felt. Cracks may run parallel or at right angles to each other.

Pump

A pump agitates the spray mixture and produces a steady flow to the nozzles. Pump parts must resist corrosion and abrasion, especially when wettable powders or similar formulations are used. Never operate a sprayer pump at speeds or pressures above those recommended by the manufacturer. You may damage the pump if it is operated dry or with a restricted flow at the inlet or outlet. Pumps depend on the spray liquid for lubrication and to prevent overheating.

Nozzles

The proper selection of a nozzle type and size is essential for proper pesticide application. The nozzle is a major factor in determining the amount of spray applied to an area, the uniformity of application, the coverage obtained on the target surface, and the amount of potential drift.

Nozzles break the liquid into droplets, form the spray pattern, and propel the droplets in the proper direction. Nozzles determine the amount of spray volume at a given operating pressure, travel speed, and spacing. Drift can be minimized by selecting nozzles that produce the largest droplet size while providing adequate coverage at the intended application rate and pressure.

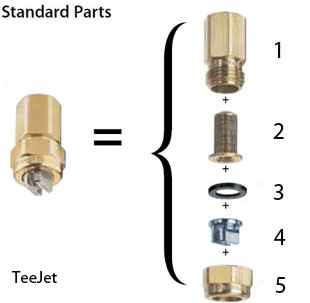

Nozzle parts:

1) The nozzle body holds the strainer and tip;

2) The strainer screen prevents a clogged nozzle. It is the best defense against nozzle plugging and pump wear. The screen can remove dirt and rust flakes from the spray liquid before it reaches the nozzle.

3) Tip gasket

4) The spray tip determines the flow rate and droplet pattern;

5) The cap holds the nozzle body and tip in place.

The Spray Tip

The spray tip determines the flow rate and droplet pattern.

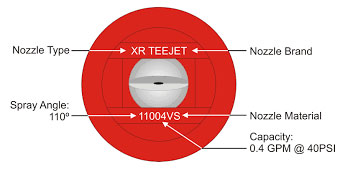

11004 nozzle

110 is the spray angle in degrees, 04 is the output-0.4 gallons per minute at 40 psi (Source: TeeJet)

Equip nozzle tips with check valves to help prevent dripping when the pump is off. Be sure the spring-loaded ball valves are working properly.

Nozzle Spray Angle, Spacing, and Boom Height

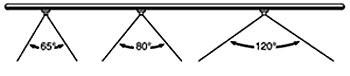

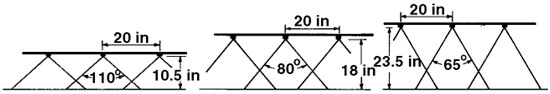

Nozzle spray angle is formed by the edges of the spray pattern. Common angles are 65°, 80°, and 120°. A wide-angle nozzle (110°) produces a thinner sheet of water with smaller droplets than a narrow angle nozzle (65°) with the same delivery rate.

Nozzle spacing on the boom, spray angle, and boom height determine proper overlap of the spray. The drawing below shows the effect of nozzle spray angle on nozzle height, need for proper overlap, and spray coverage. Notice the height difference between the 110°, 80°, and 65° nozzles. Wide angle nozzles are placed closer to the target for proper overlap. A lower nozzle height reduces the risk of spray drift.

Flow meters and other devices measure the uniformity of nozzle flow rate from nozzles along a boom. They are very useful when calibrating sprayers with multiple nozzles.

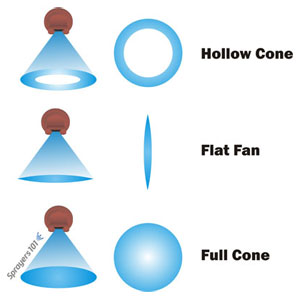

Common Nozzle Spray Patterns

Three common nozzle spray patterns: hollow cone, full cone and flat fan.(sprayers101.com)

Hollow cone nozzles produce a fine spray pattern to completely cover leaf surfaces. Full cone nozzles produce large, evenly distributed droplets at high flow rates. These two cone nozzles are best suited to apply fungicides and insecticides. Flat fan nozzles form narrow, oval patterns with tapered ends. They are spaced along a boom and overlap by 30% to 50 % for even broadcast spray distribution to the soil surface or plant canopy.

Nozzle Maintenance

Nozzles are available in various materials: brass, aluminum, plastic, stainless steel, hardened stainless steel, and ceramic. Select the material best suited for the pesticide formulation being used. Never use brass or aluminum tips to apply abrasive materials (such as wettable powders and dry flowables) because they wear too fast. This wear increases the opening size of the nozzle, which increases its output. Reduce wear by using nozzle tips made of a hard, wear-resistant material: plastic, hardened stainless steel, or ceramics.

Nozzles are available in various materials: brass, aluminum, plastic, stainless steel, hardened stainless steel, and ceramic. Select the material best suited for the pesticide formulation being used. Never use brass or aluminum tips to apply abrasive materials (such as wettable powders and dry flowables) because they wear too fast. This wear increases the opening size of the nozzle, which increases its output. Reduce wear by using nozzle tips made of a hard, wear-resistant material: plastic, hardened stainless steel, or ceramics.

Be sure you have the correct screen size for each nozzle.

Clean nozzle tips carefully with a soft brush, not wire or a knife tip.

Sprayer Cleanup

Spray equipment should be cleaned in the field after the spray job has been completed. Some pesticide labels provide specific information on cleaning spray equipment; consult the label for guidelines. Do not clean spray equipment in areas where rinse water will contaminate water supplies, streams, or injure susceptible plants.

Pay special attention to areas that can be missed or are difficult to clean:

- Spray surfaces or components where buildup of dried pesticides might occur

- Sprayer sumps and pumps

- Inside the top of the spray tank and around baffles

- Irregular surfaces inside tanks caused by baffles

- Plumbing fixtures, agitation units, etc.

- Collection points where the hoses connect to the nozzle fittings in dry boom sprayers.

Flushing spray equipment with water may be sufficient to remove potentially harmful amounts of many pesticides. However, certain groups of pesticides may require special attention. Thorough clean-out procedures can be critically important when switching applications between crops to help avoid significant crop injury. As a rule, a sprayer that has been used to apply 2,4-D or other growth regulator type herbicides should not be used to treat susceptible plants. A triple rinse – water, then ammonia, then water again – minimizes the risk of injury from dicamba and 2,4-D.

Types of Sprayers

The backpack sprayer is a simple but useful piece of application equipment made up of a tank, pump, sray wand and nozzles. It is useful for treating small areas, spot sprays, or hard to reach locations. The main spray options are broadcast, band, and spot.

The backpack sprayer is a simple but useful piece of application equipment made up of a tank, pump, sray wand and nozzles. It is useful for treating small areas, spot sprays, or hard to reach locations. The main spray options are broadcast, band, and spot.

Broadcast and band spraying spraying are used to treat areas uniformly. They require determining spray pressure, walking speed, nozzle tip, and height. Spray pressure is maintained by hand pumping. Determine a comfortable constant walking speed for the slope and terrain you will be covering. Select a nozzle tip for the volume of mixed spray that you will be applying. In many cases, the spray rate is given in teaspoons or ounces per 1,000 square feet.

Spot spraying is common for treating scattered clumps of weeds or brush. In many cases, you mix a specific concentration, such as a tablespoon per gallon of water and apply it until the foliage is wet but not dripping.

Hose reel lawn care sprayers allow efficient, even application of pesticides and fertilizers to turf. However, practice, experience, and attention to walking speed and application technique are essential for effective applications. (photo source: Turfsprayers.com)

Hose reel lawn care sprayers allow efficient, even application of pesticides and fertilizers to turf. However, practice, experience, and attention to walking speed and application technique are essential for effective applications. (photo source: Turfsprayers.com)

Common outputs for spray gun nozzles are 1.5, 3, and 4 gallons per minute. (photo source: krittenhouse.com)

Inconsistent applications can result in control failures or injury to turf or landscape plants. Things to watch for when using this type of application:

- Pump pressure is set correctly

- Consistent, accurate walking speed

- Nozzle is correct for desired flow rate

- No partially blocked nozzle openings

- Hose is not kinked

- Strainer screen is not clogged

[return]

Granular Applicators

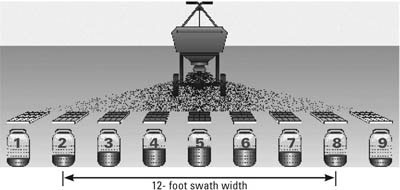

Rotary and drop spreaders (Penn State Univ.)

Rotary and drop spreaders are used to apply granular fertilizers and pesticides to turf. The spreaders have several holes in the bottom of the hoppers with moveable gates which can be set to regulate product flow. Gate openings are adjusted during the calibration process to give the proper delivery rate.

The swath of the rotary spreader is 12 feet but the distribution of the granules from it is uneven. You must overlap swaths to get an even application. The amount of overlap varies among spreaders. You need to measure the "effective swath width" of your spreader to determine the amount of overlap that is needed for uniform coverage.

Uneven distribution of granules from a rotary spreader (Pesticide Environmental stewardship-CIPM)

Lawn care products applied by drop spreaders fall directly beneath the equipment. Leaving a gap between swaths can result in streaking while overlap will double the rate.

Uneven fertilizer application: gaps between passes with a drop spreader (Donnan.com)

[return]

Non-spray Alternatives to Treating Trees

(source: modified from Utah State Univ. pub NR/FF/020)

Pesticides can be applied to tree trunks, branches, and foliage. This approach has been used extensively in recent years to protect ash trees from the emerald ash borer. Differences in chemical characteristics of products and advances in alternative application methods allow trunk implantation, trunk injection, soil injection/drenching, and trunk basal sprays. These approaches allow more efficient use of pesticides, more effective placement, especially against some borers, and elimination of drift. However, movement of some chemicals in to nectar and/or pollen can cause significant harm to pollinators.

Trunk Implants

Trunk implants or injections work by placing water soluble pesticides at or in the cambium where they can be carried through the tree mainly in xylem sap. The pesticide must be placed in the correct tree tissue at the right time of year and at an effective concentration. This tends to be a good way to treat many sap feeding insects, borers, and some caterpillars. Implantation involves placing capsules of pesticide into the outer xylem or sapwood. The product coating is dissolved by transpiration water and the chemical moved to the target site. Implants tend to require relatively large holes. (photo source: Gardenersedge.com)

Trunk implants or injections work by placing water soluble pesticides at or in the cambium where they can be carried through the tree mainly in xylem sap. The pesticide must be placed in the correct tree tissue at the right time of year and at an effective concentration. This tends to be a good way to treat many sap feeding insects, borers, and some caterpillars. Implantation involves placing capsules of pesticide into the outer xylem or sapwood. The product coating is dissolved by transpiration water and the chemical moved to the target site. Implants tend to require relatively large holes. (photo source: Gardenersedge.com)

Trunk Injection

Trunk injection involves placing pesticides into the tree for direct uptake. Injections are necessary for large trees and can be used on sites where soil treatments may not be practical, effective or appropriate, including trees growing on excessively wet, sandy, compacted or restricted soil environments. Trunk injections generally involve drilling through the bark and into the outer sapwood at the base of the tree. Drilling wounds could cause long-term damage, especially if treatments are applied annually.

Setting up a trunk injection (moorparktreeservice.com)

Application methods that rely on high pressure injections of insecticide through needles inserted into small holes may damage the tree if the pressure causes the bark to bulge and separate from the cambium. This is most likely to occur in spring and can cause larger wounds that result from death of the vascular tissue at the point of separation.

Uptake of trunk-injected insecticides will be most efficient when trees are actively transpiring. Best results are usually obtained by injecting trees in the morning when soil is moist but not saturated. Uptake will be slowed by hot afternoon temperatures and dry soil conditions. Irrigating trees during droughty conditions will help with insecticide uptake and translocation within the tree. Products applied as trunk injections are typically absorbed and transported within the tree more quickly than soil applications. Allow at least two and preferably three to four weeks for most trunk-injected products to move through the tree.

Soil Injection

Soil injection relies on placing the pesticide, diluted in water, into the soil for uptake by the root system of the tree. While no holes need to be drilled, as with implants or injections, these applications generally must be made several weeks before the pest is active to all allow time for uptake and dispersal of the chemical into the tree. In general, there is a limit to the size (diameter) of trees that can be treated by this procedure. They require specialized equipment, but offer the advantage of placing the insecticide below mulch or turf and directly into the root zone of the tree. This also can help to prevent runoff on slopes. Injections should be made just deep enough to place the insecticide beneath the soil surface (2-4 inches). Soil injections should be made within 18 inches of the trunk. Studies have shown uptake is higher and the treatment more effective when the product is applied at the base of the trunk where the density of fine roots is highest.

Hand operated soil injection device (Va Tech)

No soil applications of systemic insecticide should be made where there are roots of flowering plants that are visited by bees and other pollinators. This situation is most likely to occur where flowering plants are established around the base of an ash tree. In these situations the flowering plants should either be destroyed or insecticide should be applied via trunk injection to ensure the toxins will not be taken up by the flowering plants.

Trunk Basal Spray

The trunk basal spray alternative is based on thoroughly wetting the lower 5 feet of the trunk with a water soluble pesticide. The chemical is absorbed through the bark and distributed by the vascular system of the tree. The basal trunk spray offers the advantage of being quick and easy to apply and requires no special equipment other than a garden sprayer. This application technique does not wound the tree, and when applied correctly, the insecticide does not enter the soil. Sprayers must be calibrated to ensure the appropriate amount of the formulated product is applied to each tree.

(source: utahpests.usu.edu)

There are advantages and disadvantages to each alternative but all require largely intact vascular systems to move the pesticide.

[return]

1) The nozzle ______ determines the flow rate and droplet pattern.

2) Drift can be minimized by selecting a nozzle that produce the smallest possible droplet size.3) The strainer screen in a nozzle assembly ____________.

- increases spray pressure

- stops dripping during turnaround

- eliminates spray drift

- keeps the nozzle tip from clogging

4) The spray angle and flow rate of this nozzle is _____ degrees and ______ gallons per minute.

5) Hollow cone and full cone spray nozzles are best suited to apply pesticides evenly to the soil surface.

6) Strainer screens ARE NOT needed to catch product particles when applying only _____ formulations.

7) Which nozzle material is the best choice when applying mostly WP, DF, or WDG formulations?

8) Clean a clogged nozzle tip with a _________.

9) A check valve will help to ___________.

- keep the nozzle flow steady if the pressure drops

- reduce drift

- calibrate the nozzle

- prevent dripping when the pump is off

10) Flushing spray equipment with water is an effective way to remove residues of growth regulator herbicides.

11) Switching between granular products with smaller OR larger or lighter or heavier granules requires adjusting the flow rate of a rotary spreader.

12) A(n) _____________ application of a herbicide is the method used to kill weeds along a fence row.

13) Common outputs for hose reel lawn care sprayers are ______ gallons per minute.

14) A network of fine lines or cracks on polyethylene spray tanks indicates _____________.

- a strong tank agitator

- residues of spreader stickers

- cracking due to excessive sprayer pressure

- crazing due to sunlight and corrosive chemicals

15) Loose gravel is the best type of material to use for a pesticide containment pad.

16) _________ spraying is a common way to treat scattered clumps of weeds or localized groups of pest insects.

17) Which spreader will give a more even application of a mix of different sized or weight granules?

18) Three 30- to 60-second rinses of a sprayer with cold water minimizes the risk of injury from residues of growth regulator herbicides (2,4-D, etc.) in the tank and hoses.

19) The distribution of granules from a rotary spreader is very even across the entire swath width so no overlap is needed.

20) Trunk injections of pesticides may be necessary for __________ trees.

21) Uptake and movement of trunk-injected pesticides will be most efficient when trees are dormant.

website designed by P.M. Dillon copyright © 2016 University of Kentucky Department of Entomology

University of Kentucky College of Agriculture |

S-225 Agricultural Science Center North, Lexington, KY 40546-0091 | 859.257.7450

An Equal Opportunity University |

Last modified

11/30/2018